Harvest Guidelines

Blackberries must be harvested fully ripe since the fruit will not ripen or change color after harvest. In other words, the eating quality does not improve after harvest. Blackberries should pull easily from the plant when ripe, and the core (receptacle) should remain in the fruit.

When harvesting:

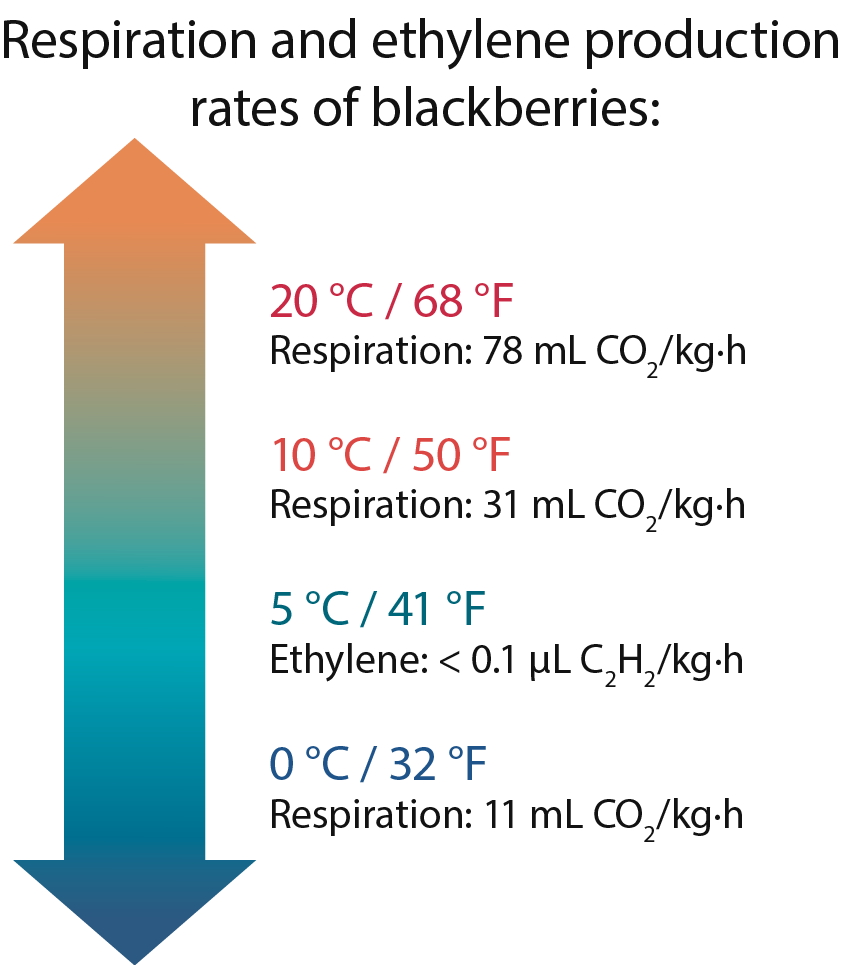

- The fruit must be rapidly cooled to 32 °F and kept cold to slow down transpiration.

- Forced-air cooling is the best method to cool blackberries.

- Avoid hydro-cooling or ice-cooling.

- Blackberries must be held at 32 °F and between 90% and 95% relative humidity to avoid water loss, reduce decay, and extend postharvest life.

- Do not allow the fruit to rewarm, as this can cause condensation, wet berries, and ultimately result in microbial growth and degradation.

Packaging

Packing should be done in the field and the packaging area must be under shade because sun exposure rapidly increases fruit temperature.

A variety of packaging containers are used to pack blackberries, but plastic clamshells are the most commonly used. Plastic clamshells are sturdy, protect the fruit from mechanical damage, do not stain, and are inexpensive. The transparency of plastic clamshells allows consumers to inspect the fruits without touching them.

A suitable packaging container is wide and shallow. No more than three layers of fruit should be packed in each container to avoid crushing the fruit on the bottom, which can cause leaking. An absorbent pad often is placed in the bottom of the container to absorb moisture and leaking juices. The pad also provides cushioning to prevent bruising and damage to the fruit. Modified atmosphere packaging for shipments with 15%–20% carbon dioxide and 5%–10% oxygen reduces the growth of decay-causing organisms.

Postharvest Issues

The most common postharvest issues in blackberries are the loss of fresh weight, red drupelet reversion, and leakiness. Fruit-rot diseases also can cause issues postharvest. The primary postharvest fruit rot on blackberries is Botrytis fruit rot. Rhizopus and Mucor also can cause a soft rot after harvest, but these pathogens are less important. Proper postharvest storage conditions are essential to reduce postharvest fruit rots caused by these fungi.

Fresh Weight Loss

Weight loss in fresh blackberries occurs rapidly because of their high transpiration and respiration rates. Moisture loss in berries causes not only fresh weight loss but also fruit shriveling, loss of gloss, and a reduction in firmness. To slow down transpiration, berries should be placed in protective packaging right after harvest and then stored under high humidity and low temperature with little air movement.

Leakiness

Leakiness limits marketability and it is increasingly likely when the fruit is exposed to high temperatures after harvest. Packing more than three layers of fruit or overfilling the clamshells can cause compression on the fruit, which in turn increases the incidence of leakiness.

Red Drupelet Reversion (Reddening)

Red druplet reversion, or reddening, is a postharvest disorder in which black drupelets—the small fleshy parts that make up a whole blackberry—revert to a red color. The causes are not fully understood, but could include exposure to room temperatures after cold storage. The disorder can be worse in some varieties and has been linked to high nitrogen fertilization rates. High-speed cold airflow tends to cause reversion on the most-exposed fruits when the berries have been damaged, either by bruising or fruit compression, during harvest or shipping. Blackberries with a core temperature above 73 °F at harvest tend to have a higher incidence of red drupelet.

References

Agricultural Marketing Service. (2018). USDA visual aid BLK-1. U.S. Department of Agriculture. https://www.ams.usda.gov/sites/default/files/media/BlackberryVisualAids.pdf

Joo, M., Lewandowski, N., Auras, R., Harte, J., & Almenar, E. (2011). Comparative shelf life study of blackberry fruit in bio-based and petroleum-based containers under retail storage conditions. Food Chemistry, 126(4), 1734–1740. https://doi.org/10.1016/j.foodchem.2010.12.071

Lawrence, B., & Melgar, J. C. (2018). Harvest, handling, and storage recommendations for improving postharvest quality of blackberry cultivars. HortTechnology, 28(5), 578–583. https://doi.org/10.21273/HORTTECH04062-18

Mitcham, E. J., Crisosto, C. H., & Kader, A. A. (1998, August). Fruit produce facts: Bushberries. University of California Postharvest Center. https://postharvest.ucdavis.edu/Commodity_Resources/Fact_Sheets/Datastores/Fruit_English/?uid=12&ds=798

Perkins-Veazie, P., Clark, J. R., Huber, D. J., & Baldwin, E. A. (2000). Ripening physiology in ‘Navaho’ thornless blackberries: Color, respiration, ethylene production, softening, and compositional changes. Journal of the American Society for Horticultural Science, 125(3), 357–363. https://doi.org/10.21273/JASHS.125.3.357